At the 1st edition of Sibca, we’ve prepared a low carbon tour to discover our latest processes developed to further reduce our environmental impact.

With an R&D department that has existed for more than 30 years and 3 million euros allocated per year, innovation is at the heart of our group’s DNA. So it was an obvious choice to take part in the first annual Sibca (Salon de l’Immobilier bas carbone), the low carbon real estate fair, at the Grand Palais Ephémère in Paris.

Our stand was designed sustainably using wood and reused materials, and it showcases the latest low carbon processes developed by the GA Smart Building and Ossabois teams.

Follow the guide!

1. Visit our 3D wood module built off-site, a master suite that reflects our future homes!

Welcome to our master suite, built using 3D modular wood construction! The 30 m² unit includes a bedroom with a study area, a rest area, storage space and an adjoining shower room. This master suite showcases the industrial know-how we bring to residential property through the leading off-site constructed low carbon housing brand.

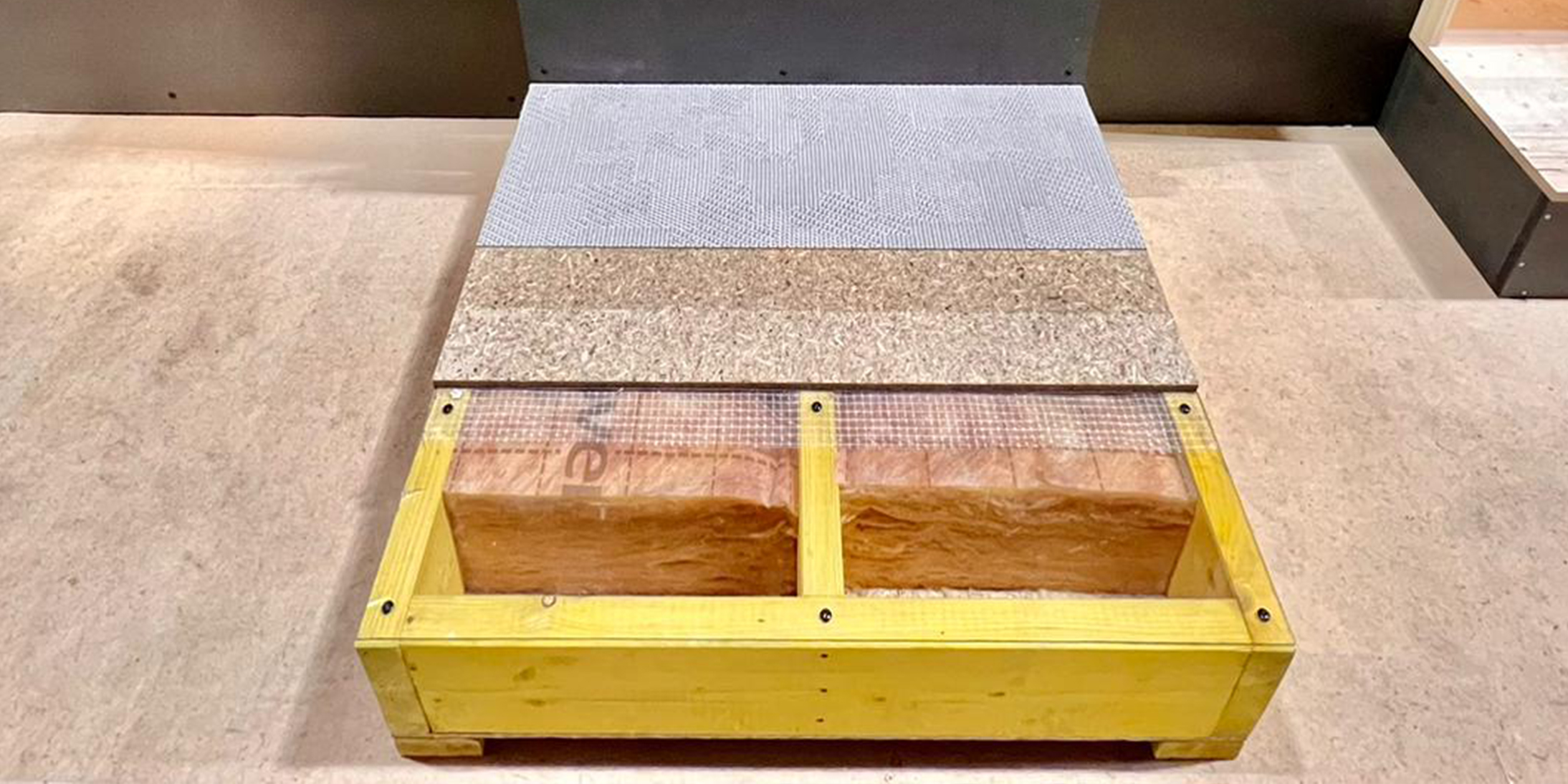

The module’s 100% wood frame structure comes from sustainably managed French forests. The wood in this module alone stores more than 2.5 tonnes of carbon.

Based on the 3D digital model, the wood-frame walls and floors were produced on the framing lines of the Ossabois factory in Noiretable in the Loire Valley, and then assembled as modules in the factory in Balbigny, also in the Loire Valley. The ensemble, including the finishing elements also produced in the workshop, was transported to the Champs-de-Mars in Paris.

The ceiling height is 2.50 m.

Off-site construction ensures industrial quality, perfect design compliance and extreme accuracy of completion. 3D modular wood reduces construction times by up to 60%, reduces noise and disturbance with 95% less structural workflow, thus relieving congestion in cities, and reduces environmental impact. The off-site construction approach also allows for better waste recovery in factories and on construction sites, as well as optimum working and safety conditions.