After minimising our waste as much as possible through our off-site construction method, we organised Circular Day to transform the remaining materials into resources

Meeting the circular economy challenge

Given the urgency of the fight against climate change and the collapse of ecosystems, and in a finite world where resources are not infinite, it is essential to recognise that those resources are being depleted and that a truly circular economy needs to be put in place.

The finding is clear: the amount of waste generated is not sustainable (46 million tonnes produced each year by the building industry*), and the cost of raw materials is soaring.

We have been committed to a sustainable and responsible strategy for several years and have already experimented with reuse solutions on our construction sites. Our waste recovery rate in factories and on construction sites is excellent (72%).

But we want to go further in our approach, which includes Circular Day.

This hackathon follows an audit carried out in our factories by the Circulab collective, which identified 13 “high-potential waste resources” and produced a data sheet for each of them with their characteristics, their current end-of-life, the impact of recycling them, etc.

Because it’s worth knowing: recycling 1 tonne of metal generates 1 tonne of CO2 emissions while recycling 1 tonne of wood only emits 0.03 tonnes of CO2. Recycling is great, but reusing materials that generate a lot of CO2 emissions during recycling is even better!

Circular Day, turning waste into resources

Circular Day began with raising our employees’ awareness of the 5 R’s of the circular economy that are growing:

- Rethink: 80% of impacts come from design

- Reduce: this means careful scaling of purchases and avoiding waste

- Reuse: continue use with the same function

- Repurpose: continue use while changing the function

- Recycle: either through material recovery or energy recovery

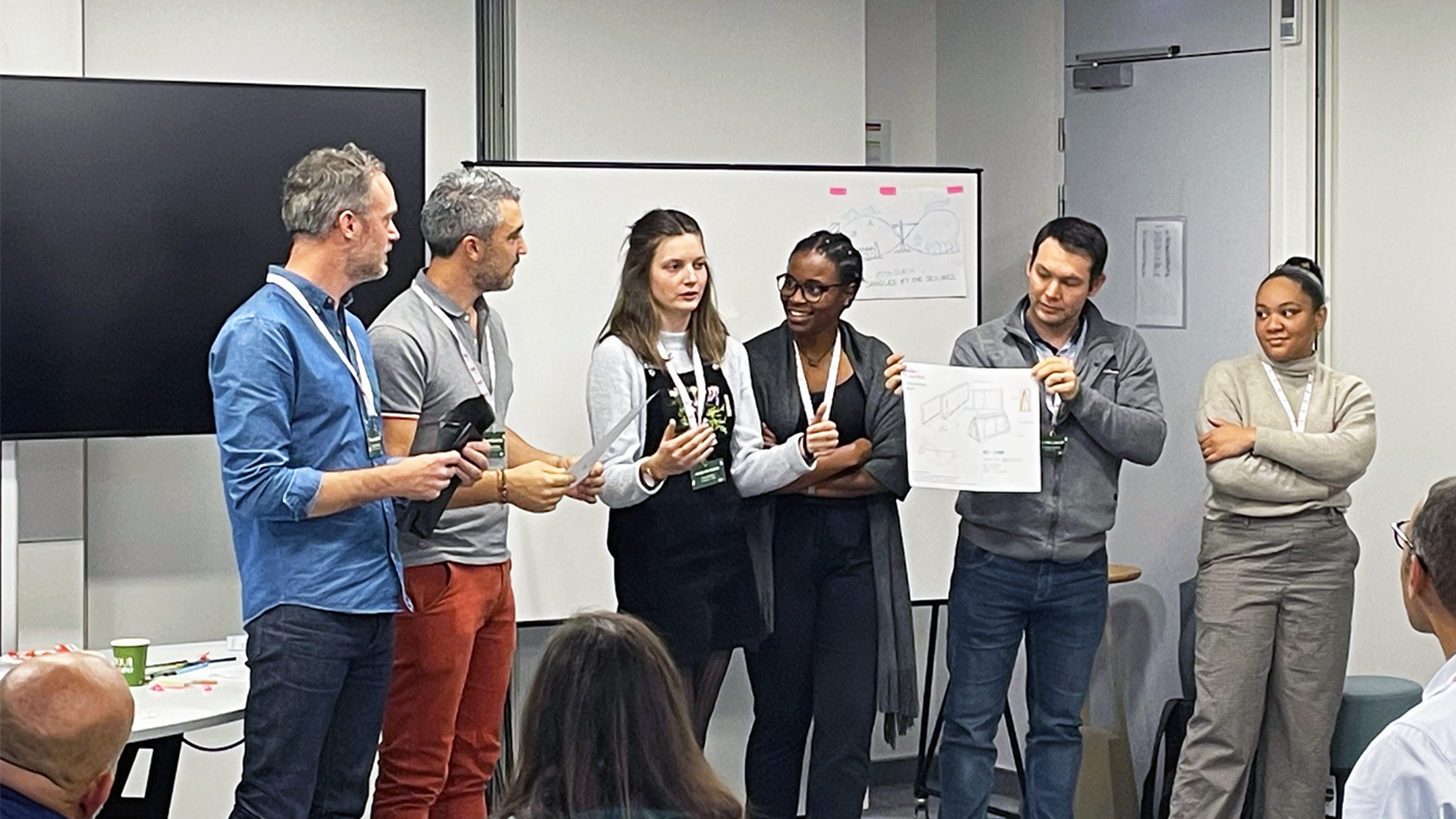

We immediately set up 6 multidisciplinary teams made up of external stakeholders (local authorities, SSEs, recycling centres, architects, urban planners, reuse platforms, carbon footprint consultancies, street furniture industry, artists, students, etc.) in addition to our employees. The event was attended by a large number of employees (design, energy and environment, purchasing, innovation and R&D, marketing, health, safety and environment teams, etc.) to whom we presented our 13 “high-potential waste resources” before launching creativity workshops to generate concrete ideas associated with a business.

Each team worked on 3 concrete projects, 18 in total! At the end of the day, they pitched one of their projects to a panel of judges headed by Sébastien Matty, Chairman of GA Smart Building. Other members of the panel were Thierry Laquitaine, President of Circolab; Élodie Le Breton, Sustainable Strategy Director, GA Smart Building; Cylien Gibert, Associate Professor in Management Sciences, specialising in strategy, Toulouse School of Management; Sébastien Mercadier, Associate Professor of Civil Engineering and engineer, INSA Toulouse; and François Minck, General Manager, Industry Unit.

The 2 winning projects are:

- ReHousse, which offers removable and adaptable covers for Ossabois 2D modules. They will replace the current protective tarpaulins, which represent about 6 tonnes of waste per year and are not reusable. With this project, the team is eliminating a waste product by rethinking its use.

- Recyclette, with the development of modular infrastructure project for tactical urban planning with no impact on public space. This project takes a global approach by integrating all waste resources.

Other outstanding projects included:

- Ecoslack, which combines our carrying straps with a mixture of sawdust from our Ossabois and Préfa factories to make insulation for the building industry.

- New Garden, which offers a 100% recycled planter that is cost-effective in its construction, yet easy to manoeuvre, to accommodate local biodiversity on a building project.

- Build for food, a truly modular micro-architecture for urban agriculture with a dedicated wellness space.

- Tr’étais, a low-tech, sturdy and height-adjustable trestle that provides ergonomic support and well-being to employees, artisans and workers.

Congratulations to everyone!

*source Ademe